For most people, flushing a toilet and turning on a tap is just a given. Twist the tap and voilà, out comes clean drinking water. Flush the toilet, problem solved.

For most people, flushing a toilet and turning on a tap is just a given. Twist the tap and voilà, out comes clean drinking water. Flush the toilet, problem solved.

But where does all of our water come from? And what happens to it after it spirals down the drain?

Turns out, it takes a complex network of pipes, wells and reservoirs to keep the cycle moving.

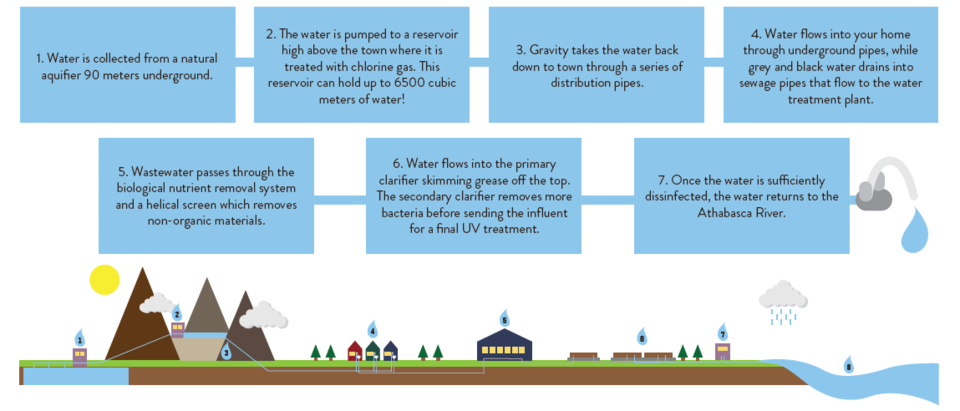

Jasper draws its water from a natural aquifer about 90 metres below the ground in the west end of town.

With three wells to draw from, the water is collected in a central pipe near Cabin Creek and is then pumped to a reservoir that sits high above town.

Inside the well house there are a number of monitors and alarms recording everything from flow rates to the reservoir levels of each well. On this particular day, the reservoir levels hover around 78 per cent.

“Essentially the reservoir is a tank and we have to preserve a certain amount [of water] in that tank for fire protection at all times and then a certain amount for domestic use,” said Bruce Thompson, director of operations for the municipality.

“Typically we fill up the reservoir in the evening, during the low peak hours, knowing that in the morning, at breakfast, there is higher demand,” he said, adding the summer season is when demand is highest, because the town services thousands of tourists, as well as its residents.

“We basically program the capacity of the reservoir to match the demand in town.”

At the reservoir, which is fenced off and buried underground, the water is treated with chlorine gas. The reservoir can hold up to 6,500 cubic metres of water at capacity and automatically refills when capacity is near 65 per cent.

“We’re very fortunate that we have high quality ground water,” said Thompson. “All that is required for us to do is inject chlorine gas into the water for disinfection.”

Once treated, gravity takes over, sending water through thousands of distribution pipes to homes, restaurants and hotels throughout town.

To ensure the water is safe to drink, the municipality takes samples five days a week from at least seven different locations throughout the municipality to make sure the residual chlorine in the distribution system complies with provincial regulations.

Once a week, the municipality also takes bacteriological samples from different locations and sends them to Alberta Health Services to be analyzed.

Because clean water is considered a critical service, the municipality has also taken steps to ensure the infrastructure works in emergencies, by installing a back up generator and a separate system of fire hydrants supplied by water from Cabin Lake.

Down the drain

Once water makes it’s way through the distribution system and is used for it’s various purposes, sewage pipes take grey and black water to Jasper’s wastewater treatment plant located in the east end of town on Cottonwood Road.

Grey water is the wastewater that goes down the drain, whether it’s coming from the kitchen sink, washing machine or the shower while black water is what’s flushed down the toilet.

The facility also collects grey and black water from the various resorts in the park that are not connected to the town’s sewage system. This includes wastewater from the cabins at Lake Edith and outhouses throughout the park.

Once at the facility, the wastewater passes through a biological nutrient removal (BNR) system, which significantly reduces the level of suspended solids and nutrients in the water.

“We’re really lucky that we have a plant that is essentially made for a city,” said Norm Pelletier, a United Water operator at the plant. The plant is designed to handle about 7,500 cubic meters of waste per day. On this particular day in May, the plant was processing 5,200 cubic meters.

The wastewater treatment plant is owned by the municipality, but operated by United Water, an American company that specializes in wastewater and drinking water treatment.

When the wastewater, also known as influent, first arrives at the plant, it passes through a helical screen that looks like a giant corkscrew, which removes any non-organic items, such as tampons, condoms and other garbage.

At the end of the process, a daily sample of the effluent is taken, as well as an influent sample, and they are analyzed in the accredited lab located on site. A composite sample of the influent and effluent water is taken over a 24-hour period to get an accurate sample of what is coming in and what is going out.

Gettin’ greasy

Once non-organic materials are removed from the wastewater, it makes its way to the primary clarifier, which is a large circular holding tank that skims grease off the top of the wastewater and sends it to two nearby vaults. It also allows for sludge and other non-soluble material to settle at the bottom.

The sludge, also known as fermented primary sludge, is eventually removed and dewatered later in the process.

From the primary clarifier, the wastewater flows into the splitter box and is separated into two combined treatment units (CTU), which each house a secondary clarifier and a bioreactor.

When the influent enters the bioreactor, a combination of active bacteria and various levels of oxygen reduce the organics and nutrients to below provincial standards.

The flow then enters the secondary clarifier where the bacteria naturally sink to the bottom while the water separates and flows over the outside edge of the clarifier. The effluent then passes through a bank of ultraviolet lights, where it is disinfected, before returning to the Athabasca River.

The process removes ammonia, nitrates, ortho phosphate, and total phosphorous from the water to ensure the biological oxygen demand (BOD) is below prescribed levels.

“It’s pretty fascinating what you can do with air,” said Pelletier. “Essentially all we’re doing is tweaking air and adjusting our different mixers and pumps based on the flows that come into the plant and what our daily lab results tell us.”

Every piece of equipment in the facility is monitored 24 hours a day by an on call operator. There is also a massive generator that can run all the essential equipment in case of a power outage.

Crap “cake”

The amount of oxygen injected into the bioreactor is based on lab results and flows as the wastewater slowly makes it way around the CTU. It takes one to three days to complete the entire circuit.

If there are any remaining solids in the wastewater after two weeks, they are caught at the end of the circuit and are sent back to the bioreactors where they go through the cycle again.

Once separated, the solids are sent to the dissolved air flotation unit (DAF) and with the help of a polymer they are pumped into the centrifuge where they are spun dry, similar to the spin cycle on a laundry machine.

The end product is called “cake”, which looks like ground up coffee beans. This is collected and mixed with wood chips.

The “cake” and wood chips are mixed in a giant mixer and eventually loaded into a dump truck and sent to the transfer station where it will be laid out to dry for five to six months.

From there, the piles are moved into a curing pile for up to 12 months or longer before being tested by an outside-accredited lab for heavy metals and salmonella. Eventually, the piles are used as “Grade B” compost.

According to Pelletier, a lot of that compost was used by Kinder Morgan as part of its reclamation work when it twinned the pipeline a few years back.

So there you have it, from the drain to the your glass.

Ultimately, it’s a dirty job, but taking Jasper’s wastewater and turning it into pristine H20 is a necessary process. It keeps the Athabasca River poop-free and the town’s drinking water safe.

Paul Clarke

[email protected]